Advanced Product Failure Analysis Testing Services

Product Details:

- Ingredients N/A (Analytical Techniques and Expertise)

- Poisonous NO

- Grade Industrial/Research

- Product Type Testing & Analysis Service

- Physical Form Service-Based (Non-Physical)

- Usage Identification of product failures, quality control, process improvement

- Properties Comprehensive defect root cause identification, detailed analytical reports, precision laboratory assessment

- Click to View more

Advanced Product Failure Analysis Testing Services Price And Quantity

- 25000.00 - 50000.00 INR/Number

- 1 Sample Number

- 500 INR/Number

- Microscopy, Spectroscopy, X-Ray Analysis, Electrical Testing, Mechanical Analysis, Thermal Analysis

- Data Security and NDA Assurance

- All Industries including Electronics, Automotive, Aerospace, Consumer Goods

- Online & Offline

- Highly Qualified Technical Analysts

- Pan India

- Detailed Digital and Printed Reports

- International and Industry Standards (ISO, ASTM, etc.)

- As per project scope

Advanced Product Failure Analysis Testing Services Product Specifications

- N/A (Analytical Techniques and Expertise)

- NO

- Identification of product failures, quality control, process improvement

- Comprehensive defect root cause identification, detailed analytical reports, precision laboratory assessment

- Product Failure Analysis for industrial and manufacturing sectors

- 998346

- Industrial/Research

- Testing & Analysis Service

- Service-Based (Non-Physical)

- Microscopy, Spectroscopy, X-Ray Analysis, Electrical Testing, Mechanical Analysis, Thermal Analysis

- Data Security and NDA Assurance

- All Industries including Electronics, Automotive, Aerospace, Consumer Goods

- Online & Offline

- Highly Qualified Technical Analysts

- Pan India

- Detailed Digital and Printed Reports

- International and Industry Standards (ISO, ASTM, etc.)

- As per project scope

Product Description

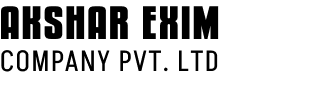

Advanced Product Failure Analysis

Experience cutting-edge diagnostics with "Pro Analytix," our Advanced Product Failure Analysis services offered by Sad guru Research and Analysis Laboratory. Designed for industries where reliability is non-negotiable, Pro Analytix provides in-depth investigations into product failures to pinpoint causes and prevent recurrence. Leveraging advanced analytical technologies and expert methodologies, our team delivers precise insights that not only solve immediate issues but also foster innovations in product design and manufacturing processes.

Features:

- Comprehensive Failure Analysis: Utilizing techniques such as fractography, metallography, and spectroscopy to identify failure modes.

- Root Cause Determination: In-depth analysis to uncover the underlying causes of product failures, from material defects to design inadequacies.

- Corrective Action Recommendations: Strategic advice based on analysis results to improve product durability and performance.

- Advanced Testing Capabilities: State-of-the-art lab equipment, including scanning electron microscopes (SEM) and energy dispersive X-ray spectroscopy (EDX).

- Industry-Specific Customization: Services tailored to meet the unique needs of sectors like aerospace, automotive, electronics, and healthcare devices.

- ISO/IEC 17025 Accredited Laboratory: Ensuring compliance with international standards for testing and reliability.

Benefits:

- Enhanced Product Safety: Reduce risks associated with product malfunctions and failures.

- Decreased Warranty Claims: Lower costs from returns and warranty claims through improved product reliability.

- Increased Customer Satisfaction: Deliver products that consistently meet or exceed customer expectations.

- Innovative Edge: Apply insights gained from failure analysis to drive product innovation and development.

FAQs:

Q: How quickly can Pro Analytix respond to a failure analysis request?

A: Our team is prepared to initiate the analysis process as soon as we receive the failed product, aiming for rapid turnaround times to minimize your downtime.

Q: What sets Pro Analytix apart from other failure analysis services?

A: Our combination of advanced technology, expert staff, and tailored approach ensures that we not only identify the problem but also provide practical, innovative solutions.

Target Customers:

- Manufacturing Executives and Engineering Teams

- Quality Assurance Managers

- Product Development Managers

- Risk Management Professionals in high-stakes industries

- Per-project pricing based on the complexity of the analysis.

- Retainer agreements for ongoing consulting and emergency analysis services.

- Training and workshops on failure prevention best practices and methodologies.

- "Advanced failure analysis services to enhance product integrity."

- "Expert diagnostics and solutions for critical product failures."

- "Tailored failure analysis for high-performance industry applications.

Don't let product failures set you back. Turn to "Pro Analytix" Advanced Product Failure Analysis Services from Sad guru Research and Analysis Laboratory for unparalleled diagnostic insights and solutions. Contact us today to schedule a consultation and discover how our precision-focused approach can help you elevate product quality and reliability. Your journey towards zero defects starts with ProAnalytix.

Comprehensive Testing Methods

Our failure analysis services incorporate microscopy, spectroscopy, X-ray analysis, electrical, mechanical, and thermal testing. This multifaceted approach enables us to thoroughly investigate and pinpoint underlying defects, ensuring accurate and actionable insights tailored to your project's specific requirements and industries.

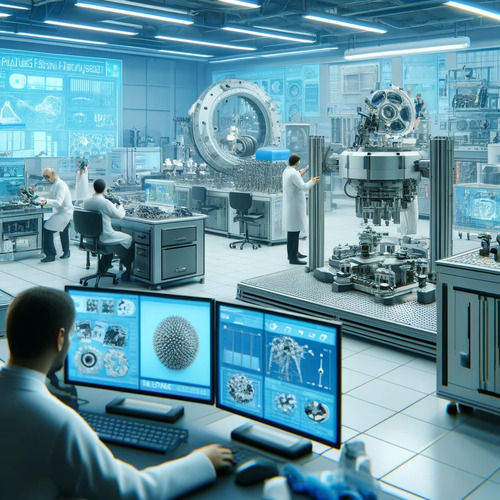

Expert Analysts & Confidentiality

With a team of highly qualified technical analysts, our services guarantee precise laboratory assessments and insightful reporting. All projects maintain strict confidentiality and adhere to NDAs, safeguarding intellectual property and sensitive business information throughout the analytical process.

Flexible Service Modes & Reporting

We offer both online and on-site (offline) modes, depending on client preferences and project needs. Each analysis includes a comprehensive digital and printed report, presenting findings, root cause identification, and actionable recommendations, supporting quality and process improvements across all sectors.

FAQ's of Advanced Product Failure Analysis Testing Services:

Q: How is product failure analysis carried out using your advanced testing services?

A: Our failure analysis process involves a combination of microscopy, spectroscopy, X-ray analysis, electrical, mechanical, and thermal testing to identify and characterize defects. Samples are examined by our expert analysts using internationally recognized standards, ensuring a precise and thorough assessment.Q: What industries do you serve with your product failure analysis services?

A: We provide comprehensive failure analysis services for all major industries, including electronics, automotive, aerospace, consumer goods, and more. Our adaptable testing approach meets the unique needs of various sectors requiring quality control and product reliability solutions.Q: When should I consider using failure analysis testing?

A: Failure analysis testing is recommended whenever you encounter unexpected product malfunctions, recurring defects, or anomalies in performance. It is also valuable for quality control, preventive maintenance, process optimization, or after field returns and warranty claims.Q: Where can your services be accessed and are they available pan India?

A: Our failure analysis services are available pan India, with both online analysis and physical sample assessment options. Clients can access our expertise remotely or request on-site support, making our services accessible wherever your operations are located.Q: What is the process for initiating a failure analysis service project?

A: To begin, clients submit a service request outlining their requirements and relevant product information. Our team coordinates the sample collection (if required), determines suitable testing strategies, conducts analyses, and delivers detailed digital and printed reports as per the agreed project scope.Q: How do your services help improve product quality and manufacturing processes?

A: By identifying the root causes of failures and providing detailed analytical insights, our services enable clients to make informed decisions for product redesign, process modifications, and improved quality control. This contributes to reduced defects, efficient manufacturing, and greater customer satisfaction.Q: What benefits do your detailed reports provide to manufacturers and suppliers?

A: Our reports offer comprehensive findings with root cause identification, actionable recommendations, and supportive data. This empowers manufacturers and suppliers to address issues efficiently, enhance product performance, and meet compliance requirements, reducing downtime and costs associated with recurring failures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS